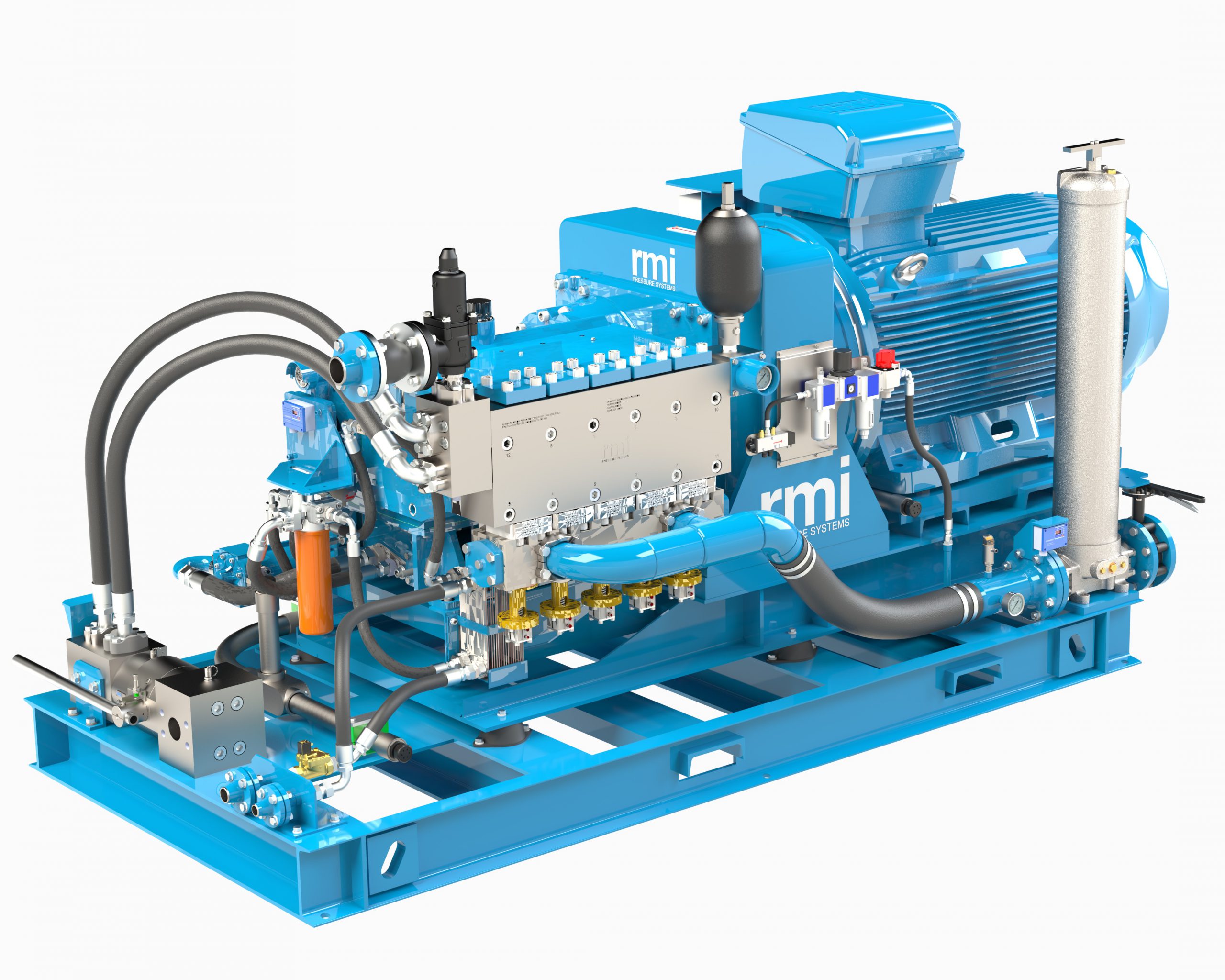

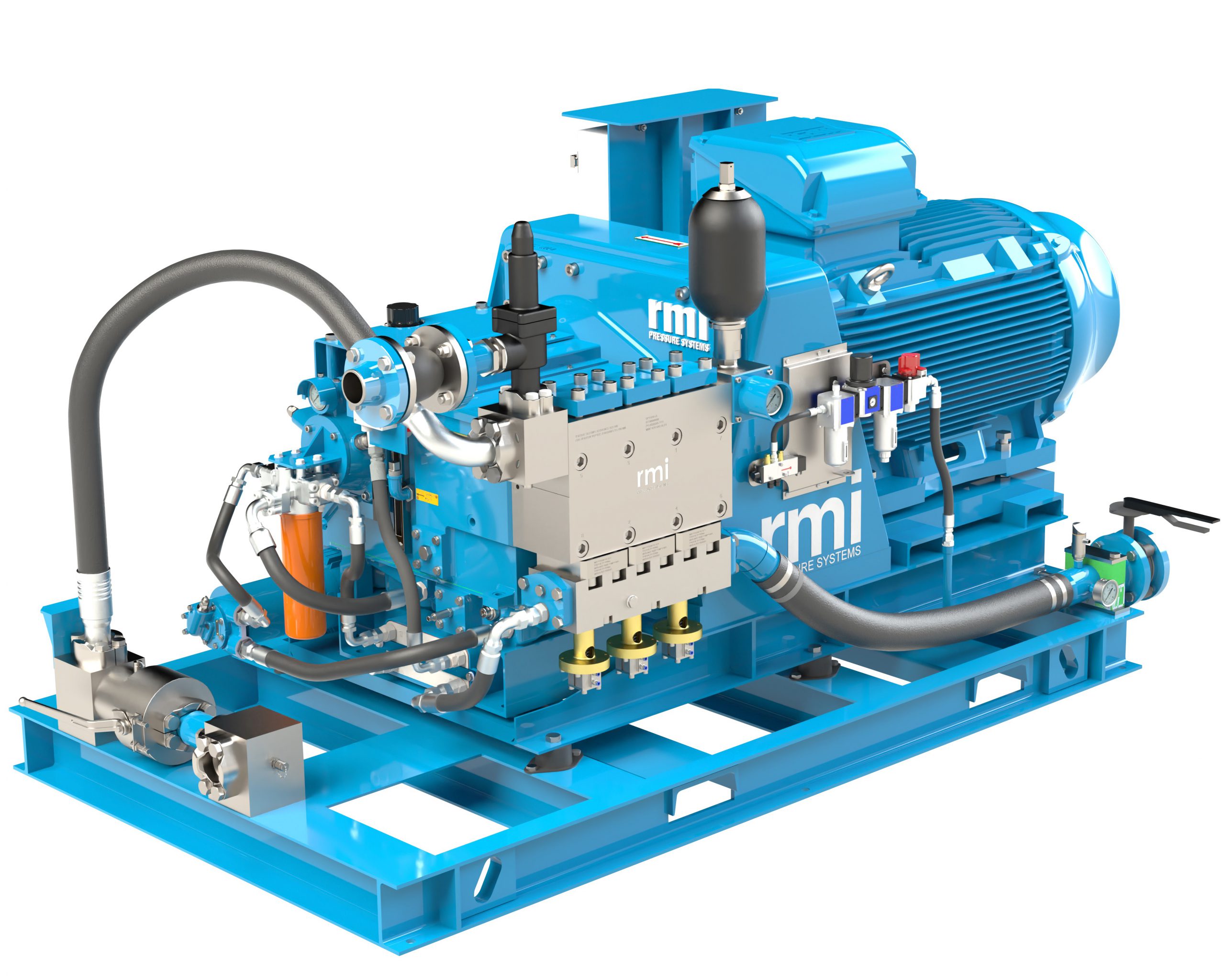

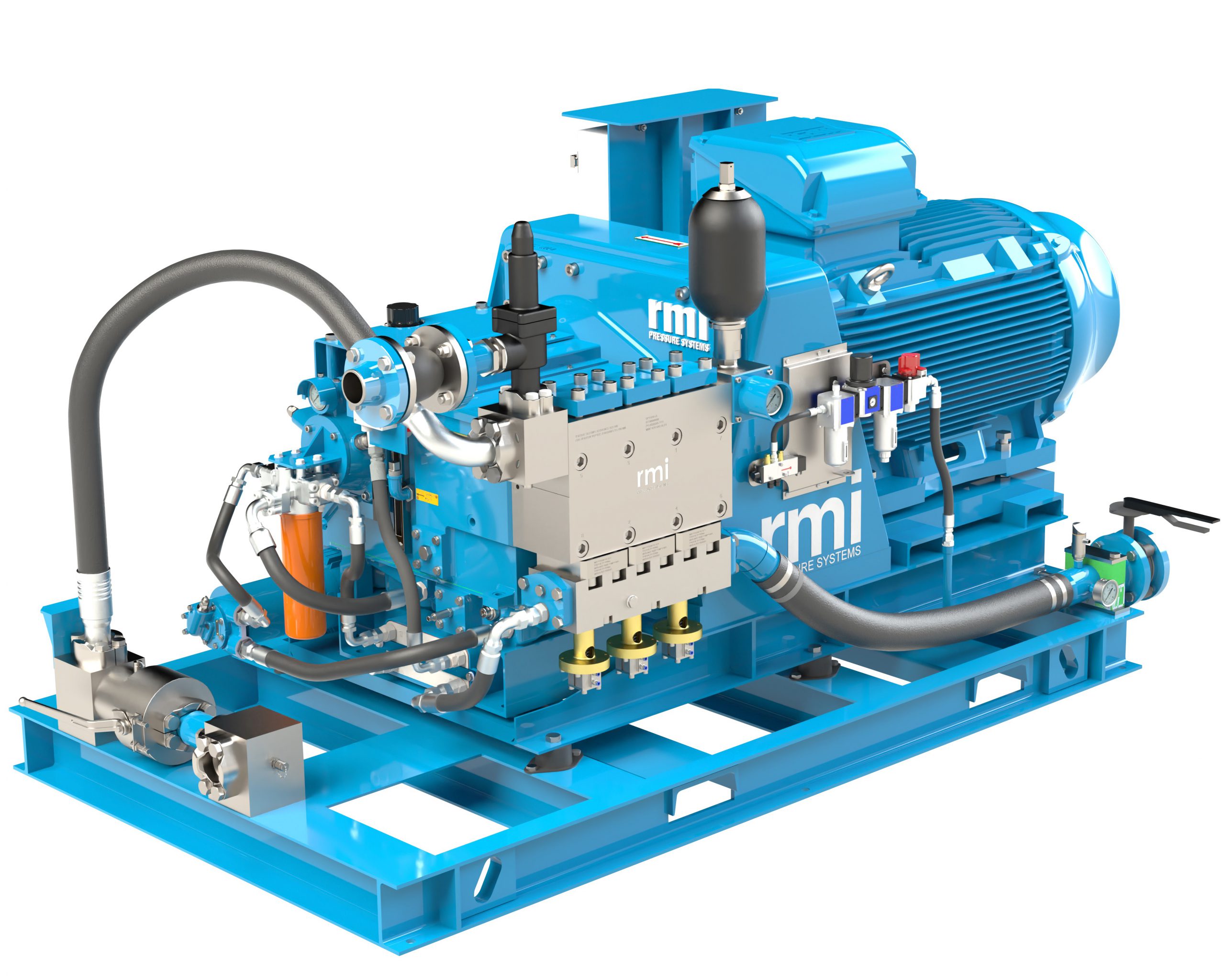

S SERIES QUINMAX S500

FIVE PLUNGER RECIPROCATING PUMP

The Quinmax S500 pump provides a safe and reliable supply of high-pressure water-based fluids for both mining and heavy industrial applications.

Its compact horizontal five-plunger design delivers power ratings up to 500hp (375kW).

- Innovative design for increased crank speeds and loading

- Drained gland well to separate the pump’s oil and fluid ends – preventing contamination

- Finite element analysis (FEA) used to validate pump performance and reliability

- Computational fluid dynamics (CFD) used to maximise efficiency of wetted components

- 40% reduction in fluid velocity reducing hydraulic noise compared to the Trimax Pumps Series

High Energy Efficiency

-

Variable frequency drives for enhanced efficiency and performance

Reliable Operation

- Designed for 24/7 duty

- Inlet pressures between 1 and 8 bar

- Forced lubrication to critical areas throughout pump

- Oil filter and heat exchanger is standard

- Health monitoring is standard, including oil temperature, level and pressure

- Smooth pressure profile, reduces wear and tear on system components (hoses, seal, valves) caused by destruction pressure surges

Quality Construction

- Valves made from high grade stainless steel for maximum life

- Valve chest made from high grade stainless steel or ENP carbon steel

- Plungers made from high purity ceramic, and rams of tungsten carbide

- Bearings have spherical roller main journals with lead bronze small and big ends

- Valve lifters fitted as an optional for safe pressure control

- Unloading valve fitted as optional for safe flow diversion

- Gland packing has self-adjusting spring-loaded Kevlar for maximum sealing

Technical Data

Description

Skid-mounted horizontal five plunger design pumping unit. High-efficiency energy through demand-based control. Remote active performance management through internet to sustain reliability and performance throughout the life of the pump.

Materials

- Valves: High grade stainless steel for maximum life.

- Valve Chest: High grade stainless steel or E.N.P carbon steel.

- Plungers: High purity ceramic plungers or tungsten carbide rams.

- Bearings: Spherical roller main journals with lead bronze small and big ends.

- Valve Lifters: Fitted as an optional, for safe pressure control.

- Unloading Valve: Fitted as an optional, for safe flow diversion. (ATEX, IECEx, MA)

- Gland Packing: Self-adjusting spring-loaded Kevlar packing, for maximum sealing

Configuration

- Pump supplied with oil filter and heat exchanger as stand

- Health monitoring including oil temperature, level and pressure as stand

- Operated with variable frequency drives to meet customer demand.

- Network enabled for remote performance management connectivity.

Performance Range

Up to 493 lpm @ 4000 bar (50 Hz model)

Temperature

Maximum operating temperature 40OC

Power

375kW (500 HP) Max

Dimensions

| S500 | |||

| Length | 1255mm (49.4”) | ||

| Width | 978mm (38.5”) | ||

| Height | 757mm (29.8”) |

You May Also Be Interested In

TRIMAX S75

TRIMAX S200

TRIMAX S250

NEED OUR HELP WITH A PROJECT?

Send us some details and we will have one of our experts contact you a.s.a.p