Industrial Applications

For decades RMI have provided robust systems to meet the customers demand, substantially reducing power consumption whilst maximising steel quality.

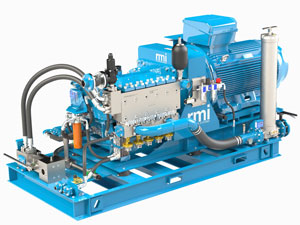

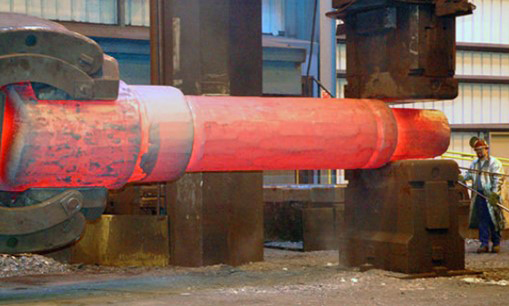

RMI provide water hydraulic pump stations and controls, which allow for the safe, smooth and controlled actuation of the press, with minimal downtown and maximum efficiency.

RMI provide water hydraulic pump stations and controls, which allow for the safe, smooth and controlled actuation of the press, with minimal downtime and maximum efficiency.

RMI provide water hydraulic pump stations and control, which allow for the safe, smooth and controlled manipulation of steel product throughout the Steel mill.

RMI provide water hydraulic pump stations and control, which allow for the reliable and efficient cooling to the Hot Saw blades to maximise blade longevity, and maintain partition quality.

RMI provide water hydraulic pump stations and controls, which allow for the safe and efficient cleaning of these critical pieces of equipment, to allow power plants to remain productive and within regulation.

Prior to implementation, the umbilical’s must be flushed and pressure tested to ensure no manufacturing defects are present. RMI provide a fully automated unit capable of both flushing and pressure testing umbilical’s, drastically reducing test times and improving productivity.

Team Contacts

USA

Liaison: Mr. Gary Punton.

Tel: +1 (205) 483-0350 ex 102

Email: gpunton@armstrongfluidtechnology.com

Address: 6599 Old Birmingham Hwy, Jasper, Alabama 35501 USA

Europe

Liaison: Kathryn Poke

Tel: +44 7951 156515

Email: Kpoke@armstrongfluidtechnology.com

Address: Address Wolverton Street, Manchester, M11 2ET, United Kingdom

China and North Asia

Liaison: Sabrina Zhang

Tel: +1 647 738 8904

Email: sszhang@armstrongfluidtechnology.com

Address: Room A050, 10th floor of Nexus Center, No. 19 of East Third Ring Rd, Chaoyang District, Beijing, China

Australia

Liaison: Mr. Huw Dodds

Tel: +61 040 056 5657

Email: hdodds@armstrongfluidtechnology.com

Address: 40 Aruma Place, Cardiff, NSW 2285, Australia

India & South Asia

Liaison: Anup Punjabi

Tel: +91 85058 95050

Email: apunjabi@armstrongfluidtechnology.com

Address: Lewis workspace, #18, 3rd floor, Off millers-Nandidurga Road, Jayamahal (CBD), Benson Town, Bangalore, India – 560 046

LATAM

Liaison: Mr. Gary Punton.

Tel: +1 (205) 483-0350 ex 102

Email: gpunton@armstrongfluidtechnology.com

Address: 6599 Old Birmingham Hwy, Jasper, Alabama 35501 USA

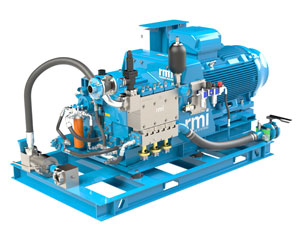

Product Solutions

S SERIES TRIMAX

S SERIES QUINMAX