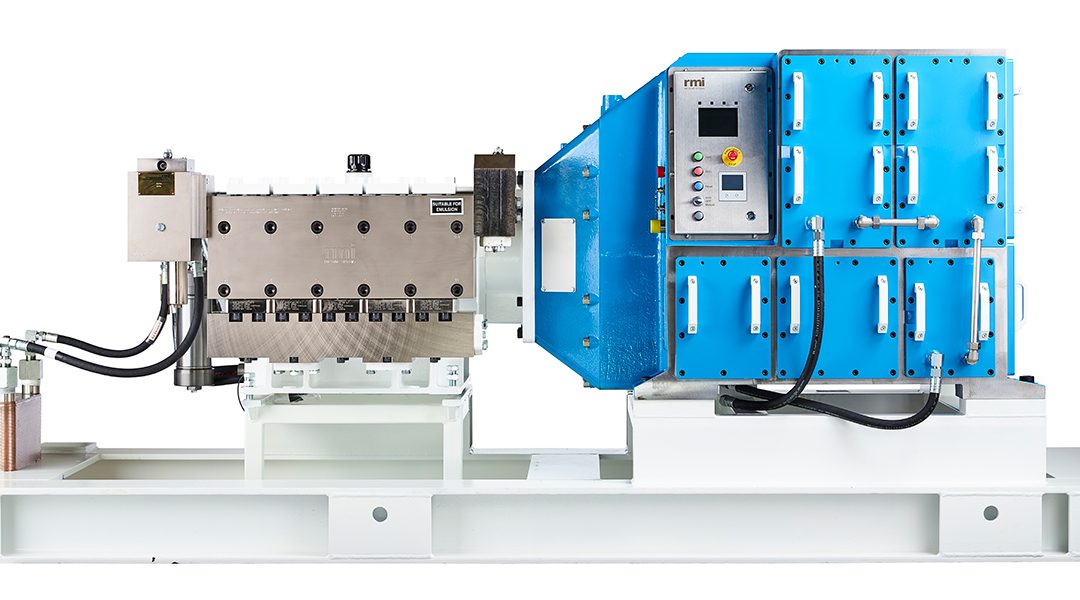

RMI has previewed the new AGILIS® fully integrated system for longwall coal mining at the recently held China Coal and Mining Exhibition 2019, in Beijing.

AGILIS is the world’s first integrated system specifically designed to increase the productivity of longwall coal mining. Using innovative industry-leading technology, AGILIS achieves unrivalled performance capability and efficiency that delivers enhanced value and profit at a lower installed cost.

AGILIS has been specifically designed to increase both uptime and productivity via an integrated smart motor drive and system controls. The system is capable of accelerating from 0 to full speed in less than 1 second, 10 times faster than the industry standard response rate. Intelligent controls and synchronised parallel pumping drive this rate of acceleration, eliminating hydraulic power lag to the roof supports and increasing uptime and productivity at the coal face.

When you consider a typical coal face extracts 8 million ton of coal every year, the increased productivity AGILIS generates, has the potential to increase profit by up to $5.6m per annum.

Real-time data is captured via SCADAä online connectivity for Active Performance Management, to monitor the operational health of the pumping system and to ensure that the equipment runs efficiently at all times. System degradation can be detected at an early stage and adjusted, to ensure maximum uptime at all times.

Lower first installation costs

Enhanced productivity cost-saving efficiency has been prioritised throughout the development of AGILIS. The plug and play design saves both labour costs and time during the initial installation and commissioning. Whilst the integrated system eliminates cables between traditional variable frequency drive (VFD) and pump motor for a lower installation cost.

Space saving

RMI pump systems are designed for confined underground spaces. The new AGILIS a smaller footprint than alternative products and built in redundancy resulting in one less pump required on a typical system and a minimum 25% space saving.

Reduced maintenance costs and replacement parts

Product life is extended through a combination of variable speed, parallel pumping operation: The pumps operate in tandem based on the system’s current needs, typically at lower speeds with reduced offloading, reducing wear and tear on system and pump components. Inbuilt ODIN® technology improves response and reduces damaged caused to seals and hoses caused by pressure surges and spikes. As a result, AGILIS maintenance schedules can be extended which reduces costs and ensures maximum uptime. Core components of the system are specifically designed as ‘plug and play’ for quick and easy replacement for when maintenance is required.

Environmental benefits

AGILIS also delivers a reduced impact on the environment. The system requires less water consumption with no external cooling being required, and the high efficiency and parallel pumping technology reduces energy consumption and therefore lowers CO2 emissions. Whereas a typical coal mine experiences a 2% loss of emulsion due to leakages, mostly caused by damage incurred to hydraulic components, AGILIS’s operating system cuts the level of emulsion loss by minimising pressure spikes on components such as seals and joints and operating noise is also lower enhancing worker safety and compliance to workplace standards.

“We’re delighted to announce the launch of AGILIS,” commented Kathryn Poke, Engineering Director at RMI. “In addition to its low operational cost and green credentials, we’re proud that the integrated system has the potential to boost coal face productivity by up to 5%. Here at RMI, we are prioritising the development of our sustainable mining portfolio and, with the launch of our latest, innovative mining technology solution, are leading the way in the digital era.”

AGILIS is a fully certified product, meeting ATEX, IECEx and MA requirements, suitable for Ex 1 M2 Ex d 1 Mb mining environments.

For more information about AGILIS, please visit www.rmipsl.com

Recent Comments